Treatments

Characterization

Performance and durability

Analytical method

The Wood Platform of the EMPP research department brings together different equipment and skills allowing the development of new materials from solid or split wood. The objective of the research developed is to improve the performance of wood and wood-based composite materials by characterizing their properties in a context of global warming and energy transition, aiming at limiting greenhouse gas emissions. It is also focused on the natural durability of wood in relation to the chemistry of extractives and the role of the latter on the properties of wood. This platform brings together a majority of the equipment available at LERMAB, which is also partly involved in the Silvatech platform labeled by Inrae and to a lesser extent in other laboratories of the cluster such as the LCPM and the LRGP.

“Material and Processes" axis

All of the experimental facilities at LERMAB enable different types of treatment to be carried out and optimized, the properties of the material to be characterized, and its performance and durability to be studied with or without accelerated ageing using various laboratory tests or analytical measurements. These devices also make it possible to study the natural durability of the material in relation to its chemical composition.

Treatments

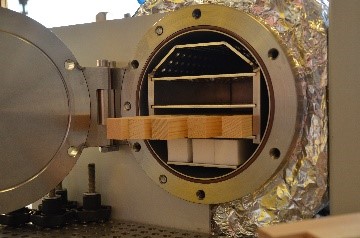

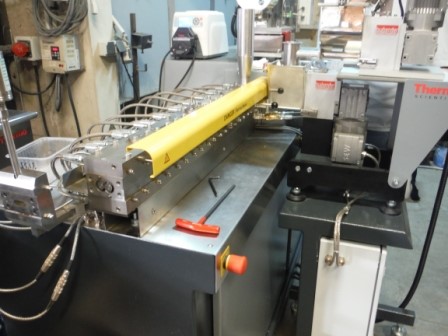

The laboratory has different vacuum/pressure impregnation or heat treatment autoclaves allowing the development of different “non-biocidal” chemical or thermal modification treatments, as well as more classical treatments involving the use of more environmentally friendly biocides. The laboratory also has equipment for the shaping of composite materials such as heating presses or extruder.

Characterization

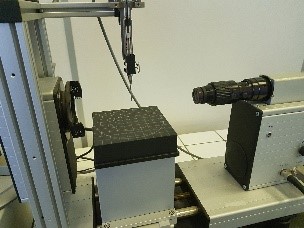

Different material characterization techniques are available to evaluate the properties of developed materials: evaluation of dimensional stability, interaction with water vapour (DVS), wettability (tensiometry, sessile drop…), mechanical properties (modulus of elasticity, modulus of rupture, Brinell hardness).

Performance and durability

The performance of the material can be characterized with or without accelerated aging test (water leaching, photoaging with QUV…). The laboratory carries out tests of conferred or natural durability against various white or brown rot fungi (laminar flow hood, climatic chamber…), measures of stability and resistance of finishes.

Analytical methods

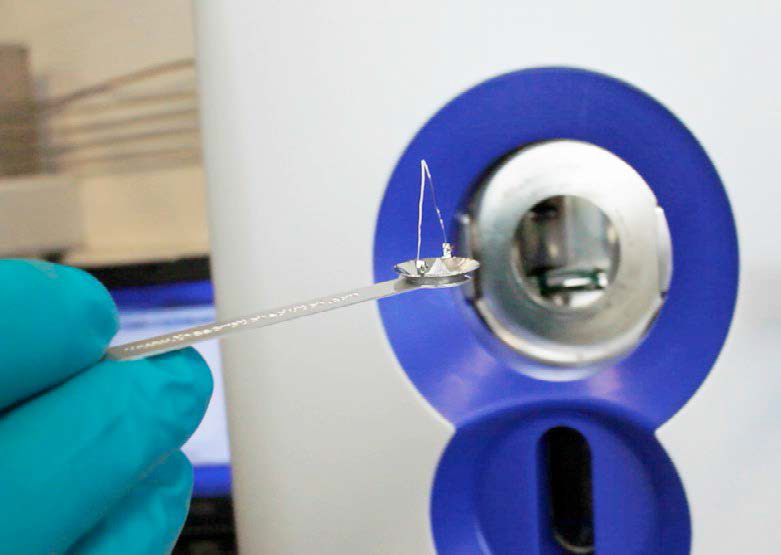

Different techniques of chromatographic analysis (GC-MS, UHPLC-MS, SEC…) or thermal analysis (ATG, DSC, Py-GC-MS…) are used to understand the properties of the material, especially concerning the role of extractives in natural durability phenomena or polymerization phenomena during different wood treatments. The laboratory is also equipped with different grinding / sieving equipments for sample preparation, as well as different extraction systems (Soxhlet, pressure extraction, microwave extraction…) and sample concentration systems (evaporation, freeze-drying, atomization…).

Various partnerships allow us to complete this service offer, particularly with regard to termite durability.