The Reactions and Process Engineering Laboratory (LRGP – CNRS/University of Lorraine) is launching a survey on the perception of 4D printing and our vision of the future. Interview with Jean-Claude André, CNRS research director and Azran Mostapha, Malaysian student at ENSIC who tell us more.

3D printing was invented in 1984 at the DCPR (which was integrated into the LRGP ten years ago), this digital technology consists of the automated addition of material that transforms locally (for example from liquid to solid), hence its name “additive manufacturing”. If, at the time, France did not find the idea interesting, this first patent was put in the public domain. The industrial development was therefore in this period essentially American. But the Nancy site remained active with work, partly in common with the LRGP, the IJL and the LORIA. The pioneering spirit remains strong.

Fact: what is 4D printing?

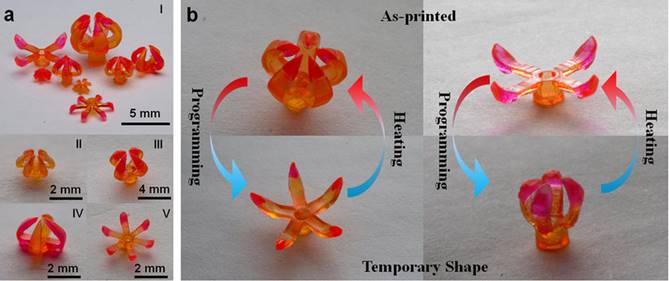

Jean-Claude André and Azran Mostapha: “3D printing makes it possible to create objects with very complex shapes using passive materials (polymers, ceramics, metals, alloys, etc.). The new idea (which would come from the University of Bath in England in 2012) is to add functionality to materials (called active, stimulable, smart, intelligent) which can thus see their shape or functionality change under external stimulation (see figure). It took about 25 years for additive manufacturing to develop (a market of 30 billion €/year) and today we are at about 100 million €/year for 4D, but with a rate of publications increasing by 40%/year. However, we are still far from Terminator 2 with global (and not localized) stimulation and materials that are too soft and with too low response times, but it works and it is spectacular. What we are looking for today (with the same accomplices from the UL, but also from the UTBM, Sorbonne-University, the universities of Brittany, INSA-Lyon, Grenoble, Marseille, etc.) is to break the locks presented above. But they are (too) numerous.

To know more about it